Solar Carport Bracket

The solar carport on the roof can be used effectively. The solar cell module can be installed efficiently without wasting space. TMM's "Solar Carport Bracket" is also compatible with the latest large modules. With reliable strength design, operability during installation and assembly is also considered. It provides a 10-year warranty.

Provide safe products based on reliable design standards

-

1

Solid design standards

The design is based on aluminum building structure design standards and reviews (published by the Aluminum Building Structure Committee and supervised by the Institute of Land Resources Management and the Institute of Land Infrastructure Management, Ministry of Land, Infrastructure, Transport and Tourism).In addition, part of "JIS C 8955-2017" is also compliant.

-

2

Designed to meet customer needs

We have a system that can flexibly support the latest solar cell modules. We will design according to various requirements such as installation location and output scale.

-

3

Fully consider site workability/assembly workability

It is a specification that considers operability when installing and assembling the rack.

Solar shared bracket

To share solar energy, erect a pillar on the farm and install solar cell modules on top of it. As a sustainable measure to enable solar power generation and agricultural production to coexist, it has attracted widespread attention throughout the country. TMM's "Solar Sharing Bracket" has a reliable strength design and is easy to install and assemble. This product comes with a 10-year warranty.

Provide safe products based on reliable design standards

-

1

Solid design standards

Our design complies with "JIS C 8955-2017".

-

2

Designed to meet customer needs

We have a system that can flexibly support the latest solar cell modules.We will design according to various requirements such as installation location and output scale.

-

3

Fully consider site workability/assembly workability

It is a specification that considers operability when installing and assembling the rack.

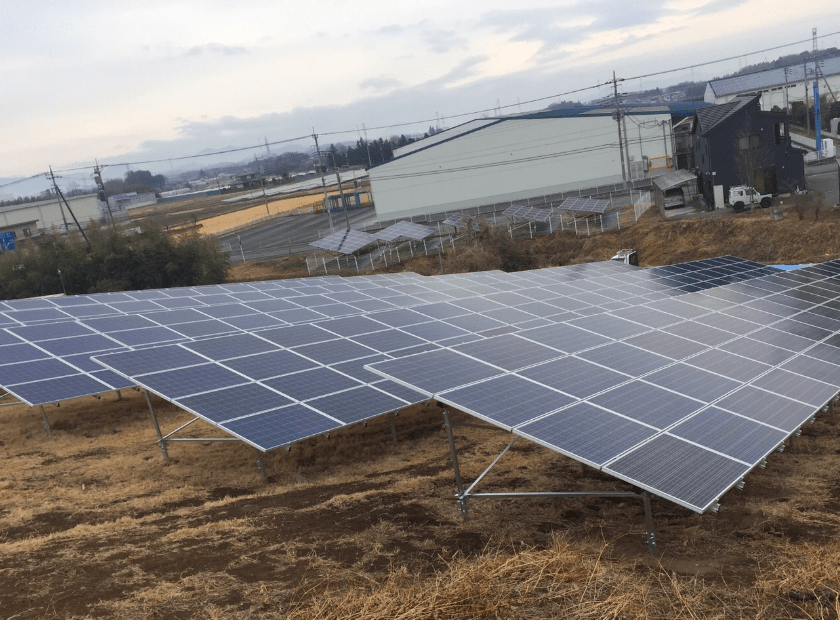

Field slope

TMM's "Slope Mount" can mount modules at a stable angle even on complex outdoor terrain (such as mountains and hills). The 360-degree angle-adjustable joints and height-adjustable pillars expand the possibilities of power generation facilities. Of course, this product comes with a 10-year warranty.

Provide safe products based on reliable design standards

-

1

Reliable strength design

Excellent gantry strength!It can withstand a snow load of up to 100 cm. Comply with the design standard "JIS C 8955-2017".

-

2

Consider the operability during installation/assembly

The on-site tilting base system saves you the trouble of preparing to install the ground, and also saves time and money.Compared with traditional products, the construction time has been shortened by 15% to 20% (user evaluation results).

-

3

Adjustable joints and struts for flexible module installation

The adjustment joint designed by TMM (purchased utility model) can be adjusted freely, the azimuth angle is 360 degrees, and the inclination angle is 40 degrees. In addition, the height of the column can be adjusted in 3 levels, making it flexible on various slopes.即使在东西向的斜坡上,您也可以轻松安装高效的光伏发电系统。

Standard field bracket

TMM's "Standard Field Bracket" has a design system that can flexibly support the latest modules. We will arrange according to various requirements such as installation location and output scale. Of course, the strength design is safe, while also considering the operability during installation and assembly. This product comes with a 10-year warranty.

Provide safe products based on reliable design standards

-

1

Solid design standards

Our design complies with "JIS C 8955-2017".

-

2

Designed to meet customer needs

We have a system that can flexibly support the latest solar cell modules.We will design according to various requirements such as installation location and output scale.

-

3

Fully consider site workability/assembly workability

It is a specification that considers operability when installing and assembling the rack.

Flat top bracket (industrial use)

Flat roof brackets installed on the roofs of buildings, apartments, school buildings, etc. As the traditional construction method, foundation construction method and anchor bolt drive are the mainstream, but TMM's "flat roof base (industrial)" adopts the construction method without foundation and anchor rod. Therefore, there is no risk of rainwater leakage without damaging the building. This product comes with a 10-year warranty.

Provide safe products based on reliable design standards

-

1

Reliable strength design

It can handle wind speeds of 40 m/s and snow loads up to 70 cm. Comply with the design standard "JIS C 8955-2017".

-

2

Consider the operability during installation/assembly

Construction is just assembly and installation.You can use an elevator because it is made of lightweight aluminum and can be moved onto the roof. No maintenance is required, and the construction time is reduced by 50% to 75% compared with conventional construction methods (user evaluation results).

-

3

Roof construction without ground anchors or foundations (maximum installation height 60m)

In addition to wind pressure fixation (verified by wind tunnel experiments) and wire fixation, the gantry is also fixed with strong butyl tape. By covering all the front, back and sides of the solar cell module with galvanized steel sheet, the wind blowing to the back is shut off.Its characteristic is that the solar cell module does not generate buoyancy and only applies a load toward the roof surface.